Table of Contents

- 1. What Exactly is an Empty Palm Fruit Bunch (EFB)?

2. The Journey: How is an Empty Palm Fruit Bunch Processed?

3. Top 5 Revolutionary Uses of an Empty Palm Fruit Bunch

4. The Dual Impact: Environmental and Economic Benefits

5. What’s Next? The Future of Empty Palm Fruit Bunch Technology

6. Your Source for Sustainable Palm Products

7. Frequently Asked Questions

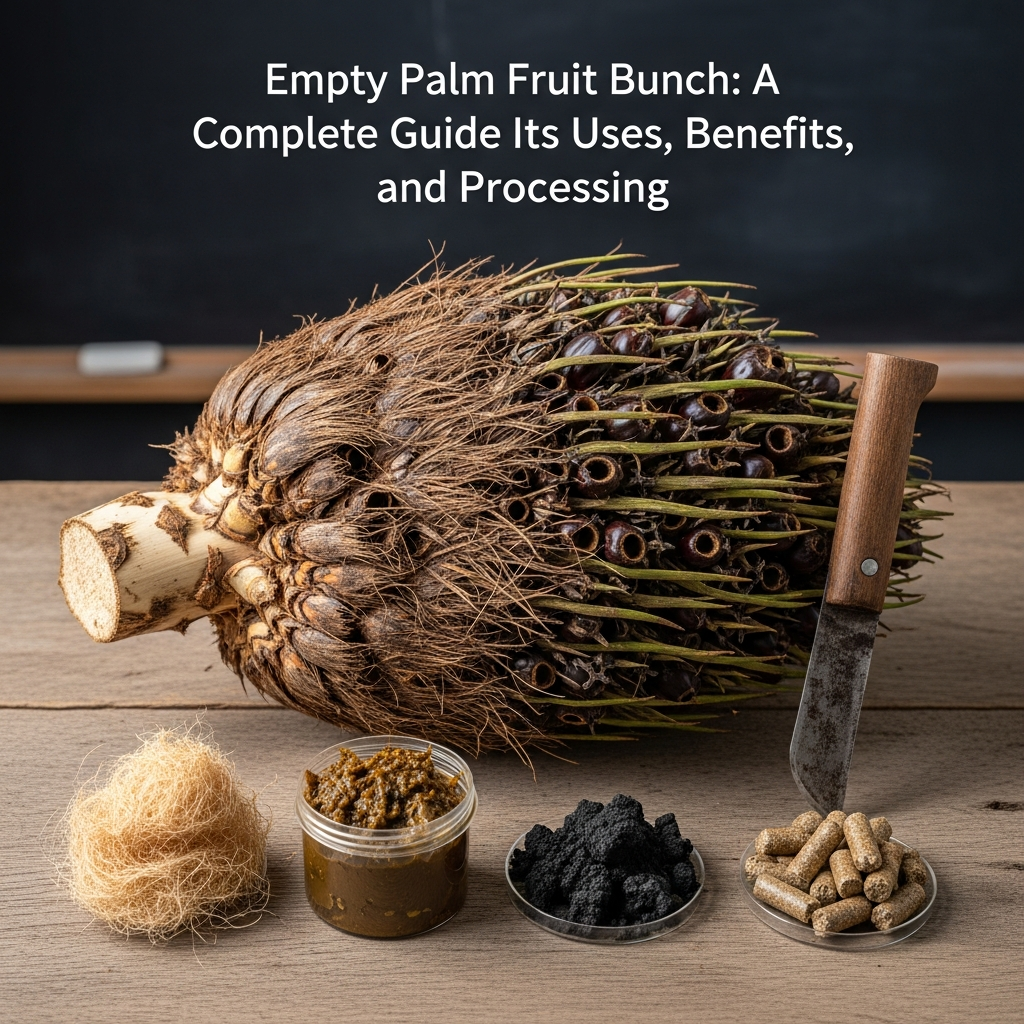

The palm oil industry is a global giant, but its production cycle generates enormous amounts of biomass. For years, one of its primary byproducts was seen as mere waste. We’re talking about the empty palm fruit bunch (EFB), the fibrous husk left behind after the valuable fruitlets—which are processed into Crude Palm Oil and Palm Kernel Oil—are harvested. This guide delves into how this humble agricultural residue is transforming into a valuable resource, championing sustainability and innovation.

1. What Exactly is an Empty Palm Fruit Bunch (EFB)?

An empty palm fruit bunch is the stalk of the palm fruit, which becomes “empty” once the fruitlets (containing the valuable Palm Kernel) used for oil extraction are removed. These bunches are a lignocellulosic material, primarily composed of cellulose, hemicellulose, and lignin. They are tough, fibrous, and incredibly abundant in regions with significant palm oil cultivation.

Historically, EFB was either left to rot in plantations or incinerated, causing significant environmental concerns like greenhouse gas emissions and air pollution. However, a shift towards a circular economy has highlighted the immense, untapped potential of every single empty palm fruit bunch produced.

2. The Journey: How is an Empty Palm Fruit Bunch Processed?

Transforming a raw, moisture-laden empty palm fruit bunch into a usable product requires a multi-step process. The primary goal is to reduce its size and moisture content, which can be as high as 60-70% initially. This makes it more efficient to transport and use as a feedstock for various applications.

Step 1: Collection and Shredding

The process begins at the palm oil mill, where EFB is collected directly from the production line. It is then fed into shredders or chippers that break down the large, bulky bunches into a more uniform, smaller fiber size. This step is crucial as it increases the surface area, which aids in the subsequent drying process.

Step 2: Dewatering and Drying

After shredding, the EFB fibers are often pressed to mechanically squeeze out excess water. Following this, they are sent to a rotary dryer to reduce the moisture content to below 20%. Proper drying is essential for preventing decomposition and preparing the empty palm fruit bunch fiber for its end use, especially as a biofuel. For more technical details on biomass processing, this study from ScienceDirect offers deep insights.

Step 3: Pelletizing (Optional)

For biofuel applications, the dried EFB fiber is often compressed into dense pellets or briquettes. This pelletizing process increases the energy density of the material, making it easier to handle, store, and transport compared to the loose fiber. These pellets are an eco-friendly substitute for coal in industrial boilers.

3. Top 5 Revolutionary Uses of an Empty Palm Fruit Bunch

The true value of an empty palm fruit bunch lies in its versatility. Advances in technology have unlocked numerous applications, turning this byproduct into a sought-after commodity.

1. Biofuel and Renewable Energy

This is perhaps the most significant use. An empty palm fruit bunch can be directly combusted in power plant boilers to generate electricity and steam, reducing reliance on fossil fuels. As a carbon-neutral fuel, it releases approximately the same amount of carbon during combustion as the palm plant absorbed during its growth. The International Renewable Energy Agency (IRENA) highlights biomass like EFB as a key player in the global energy transition.

2. Composting and Soil Conditioning

When composted, EFB decomposes into a nutrient-rich organic fertilizer. Its high organic matter content improves soil structure, water retention, and aeration, making it an excellent soil conditioner for agriculture. This practice returns vital nutrients to the soil, promoting healthier crop growth and reducing the need for chemical fertilizers.

3. Pulp and Paper Production

The fiber from an empty palm fruit bunch is a viable alternative to wood in the pulp and paper industry. Using EFB helps reduce deforestation and provides a sustainable source of raw material for producing paper, cardboard, and other packaging materials. Organizations like the Technical Association of the Pulp and Paper Industry (TAPPI) explore such non-wood fibers extensively.

4. Biocomposite Materials

EFB fibers can be combined with polymers to create biocomposite materials. These materials are used to make a variety of products, from furniture and automotive interior parts to decking and construction materials. They are lightweight, durable, and more environmentally friendly than traditional plastics or wood-based composites.

5. Mushroom Cultivation Medium

The sterilized and composted fiber of an empty palm fruit bunch serves as an excellent substrate for growing edible mushrooms, such as oyster mushrooms. The EFB provides the necessary nutrients and physical support for the mycelium to thrive, creating another value-added product from this versatile biomass.

4. The Dual Impact: Environmental and Economic Benefits

The proper utilization of the empty palm fruit bunch offers compelling benefits. Environmentally, it mitigates landfill waste, reduces methane emissions from decomposition, and provides a renewable energy source that displaces fossil fuels. This approach is central to creating sustainable agriculture practices within the palm oil sector.

Economically, it creates new revenue streams for palm oil mills, reduces their waste disposal costs, and fosters job creation in collection, processing, and logistics. It’s a clear win-win, turning an environmental liability into an economic asset, as noted by the Food and Agriculture Organization (FAO) in discussions about organic waste recycling.

5. What’s Next? The Future of Empty Palm Fruit Bunch Technology

The innovation surrounding the empty palm fruit bunch is far from over. Researchers are actively exploring advanced applications, including the production of biofuels like bioethanol, the extraction of valuable biochemicals, and the creation of nanocellulose for high-tech materials. As technology evolves, the empty palm fruit bunch will play an even greater role in building a sustainable, bio-based economy.

6. Your Source for Sustainable Palm Products

Looking for High-Quality Palm Products?

Makmur Amanah Sejahtera provides high-quality palm products such as Palm Kernel Expeller, Palm Kernel Shell, Crude Palm Oil, Palm Kernel Oil, etc. Kindly contact us at WhatsApp +6282140002198 or email us at admin@makmuramanah.co.id.

7. Frequently Asked Questions

Q: What is the main difference between an empty palm fruit bunch and palm kernel shells?

A: An empty palm fruit bunch is the soft, fibrous stalk left after fruitlet removal. In contrast, a Palm Kernel Shell is the hard, woody covering of the fruit’s kernel. While both are excellent biofuels, EFB is also used for composting and fiber-based products. The kernel itself, once crushed for oil, produces another valuable byproduct: Palm Kernel Expeller, used in animal feed.

Q: Is using EFB for energy truly environmentally friendly?

A: Yes, it is considered a carbon-neutral process. The carbon dioxide released during combustion is part of the natural biogenic carbon cycle, unlike the burning of fossil fuels, which releases long-sequestered carbon into the atmosphere.

Q: How much energy can be generated from an empty palm fruit bunch?

A: The energy content (calorific value) of a dried empty palm fruit bunch is typically around 16-18 MJ/kg. This makes it a potent fuel source for industrial boilers and power generation, significantly reducing the carbon footprint of energy production.