Table of Contents

Table of Contents

- First, What is RBD Palm Oil?

- Olein vs. Stearin: The Fractionation Process Explained

- A Deep Dive into RBD Palm Olein CP8

- RBD Palm Olein CP8 vs. CP6 vs. CP10: The Ultimate Comparison

- Primary Applications of RBD Palm Olein CP8

- Discover Other Valuable Products from the Oil Palm

- Sustainability in the Palm Oil Industry

- Conclusion: Why Choosing the Right CP Level Matters

If you’ve ever looked into the world of edible oils, you’ve likely encountered a sea of acronyms and technical terms. One of the most common yet misunderstood products is RBD Palm Olein CP8. This versatile cooking oil is a staple in kitchens and food manufacturing facilities worldwide, but what exactly is it, and how does it differ from its siblings, CP6 and CP10? This guide breaks down everything you need to know.

Understanding the properties of RBD Palm Olein CP8 is crucial for both consumers and industrial buyers to select the perfect oil for their specific needs, from deep frying to creating the perfect salad dressing. Let’s dive in.

First, What is RBD Palm Oil?

Before we can understand the specifics of CP8, we need to start with the basics. The journey of palm oil begins with the fresh Oil Palm Fruit Bunch, from which the initial oil is extracted. This raw oil, known as Crude Palm Oil, then undergoes a purification process to make it suitable for consumption. The “RBD” in the name stands for Refined, Bleached, and Deodorized.

- Refining: This step removes free fatty acids (FFAs) and impurities that can cause the oil to smoke or go rancid quickly.

- Bleaching: The oil is filtered through bleaching earth (a type of clay) to remove natural pigments like carotenoids, resulting in a light, golden-yellow color.

- Deodorizing: Steam is used under a vacuum to strip away any remaining odors and tastes, producing a neutral, bland oil that won’t interfere with the flavor of food.

The end product is a stable, versatile oil. But to get products like RBD Palm Olein CP8, it must undergo another critical step: fractionation. For more on this, you can explore the detailed chemistry of edible oil refining processes.

Olein vs. Stearin: The Fractionation Process Explained

Fractionation is a physical process that separates the oil into different “fractions” based on their melting points. RBD palm oil is slowly cooled, allowing the parts with higher melting points to crystallize.

These crystals are then separated, yielding two main products:

- Palm Olein: The liquid fraction, which has a lower melting point and stays liquid at room temperature.

- Palm Stearin: The solid fraction, which has a higher melting point and is used for products like margarine and shortening.

The “CP” in our focus keyword, RBD Palm Olein CP8, stands for Cloud Point. This is the temperature at which the oil starts to appear cloudy or hazy as it cools. This metric is the primary way different grades of palm olein are classified.

A Deep Dive into RBD Palm Olein CP8

RBD Palm Olein CP8 has a cloud point of 8° Celsius (46.4° F). This means the oil will remain clear and liquid at temperatures above 8°C. Below this point, it will begin to solidify and look cloudy. This characteristic makes it an excellent all-purpose oil, especially in temperate and tropical climates.

Its balance of properties makes it highly sought after. It is more resistant to oxidation than oils with lower cloud points, giving it a longer shelf life and making it great for frying. Yet, it remains liquid in most ambient conditions, making it easy to pour and use in various food applications.

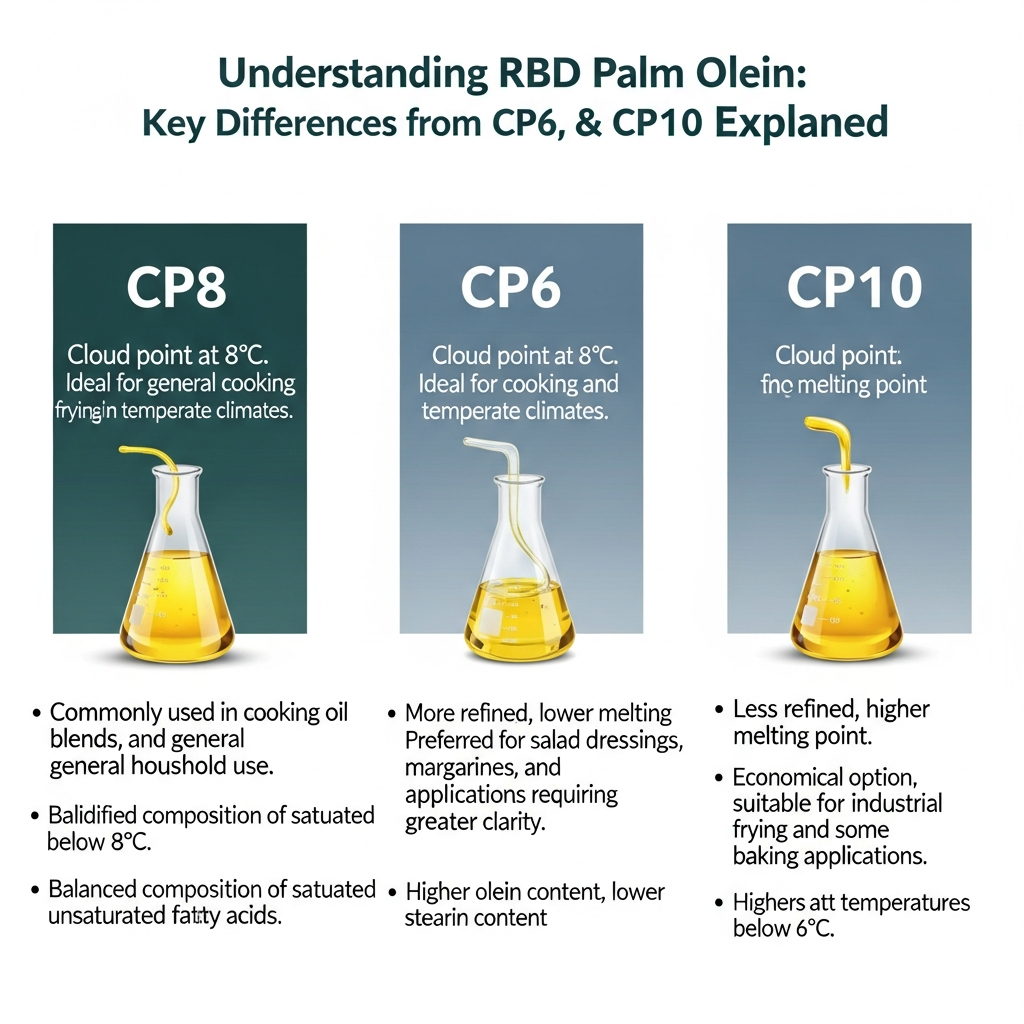

RBD Palm Olein CP8 vs. CP6 vs. CP10: The Ultimate Comparison

The main difference between CP6, CP8, and CP10 is their performance in different temperatures. This is a direct result of the extent of the fractionation process they undergo. Let’s look at each one.

Understanding RBD Palm Olein CP6

With a cloud point of 6°C, CP6 is the most liquid of the three. It is put through a more intensive fractionation process to remove more solid fats. This makes it remain clearer for longer in cooler conditions.

Best for: Colder climates, salad dressings, mayonnaise, and any application where maintaining liquidity at low temperatures is essential.

Understanding RBD Palm Olein CP10 (Super Olein)

Often referred to as standard olein, CP10 has a cloud point of 10°C. It contains more solid fats than RBD Palm Olein CP8, making it slightly more viscous. While it clouds up more easily in cool weather, this composition gives it exceptional stability at high temperatures.

Best for: Hot climates, deep frying, and industrial food processing (e.g., instant noodles, chips) where oils are kept at consistently high temperatures.

At-a-Glance Comparison Table

| Feature | RBD Palm Olein CP6 | RBD Palm Olein CP8 | RBD Palm Olein CP10 |

|---|---|---|---|

| Cloud Point | 6°C (Maximum) | 8°C (Maximum) | 10°C (Maximum) |

| Low-Temp Performance | Excellent (Stays liquid) | Good | Fair (Clouds easily) |

| High-Temp Stability | Good | Very Good | Excellent |

| Common Uses | Salad oils, mayonnaise, bottling in cool climates | All-purpose cooking, shallow frying, food manufacturing | Deep frying, industrial frying, hot climates |

Primary Applications of RBD Palm Olein CP8

The versatility of RBD Palm Olein CP8 makes it a true workhorse in the food industry. Its balanced profile allows it to be used in a wide range of applications without compromising on quality or performance.

Some of its most common uses include:

- General Cooking & Frying: It has a high smoke point (around 235°C or 455°F), making it perfect for sautéing, pan-frying, and deep-frying.

- Food Manufacturing: It’s a key ingredient in baked goods, confectionery, non-dairy creamers, and infant formula.

- Cooking Oil Blends: It is often blended with other vegetable oils to improve their stability and shelf life.

Discover Other Valuable Products from the Oil Palm

While this guide focuses on RBD Palm Olein derived from the palm fruit’s flesh, the oil palm is a source of many other valuable materials. The fruit’s nut, or Palm Kernel, is processed to produce Palm Kernel Oil, a distinct product with its own unique properties and applications. The leftover solids from this process are known as Palm Kernel Expeller, a high-protein ingredient widely used in animal feed. Even the hard casing, the Palm Kernel Shell, is valued as a high-grade, eco-friendly solid biofuel.

Sustainability in the Palm Oil Industry

No discussion about palm oil is complete without addressing sustainability. The industry has faced scrutiny over deforestation and habitat loss. In response, organizations have emerged to promote responsible cultivation and production.

When sourcing any palm oil product, including RBD Palm Olein CP8, it’s important to look for certifications like the Roundtable on Sustainable Palm Oil (RSPO). The RSPO sets global standards for producing and sourcing certified sustainable palm oil (CSPO) to protect the environment and local communities.

Conclusion: Why Choosing the Right CP Level Matters

In summary, RBD Palm Olein CP8 stands out as a highly versatile and popular edible oil due to its balanced cloud point. It offers an ideal compromise between the cold-weather resistance of CP6 and the high-heat stability of CP10.

Whether you’re a food manufacturer looking for a reliable frying medium or a home cook in a temperate climate, RBD Palm Olein CP8 provides excellent performance and value. Understanding these key differences ensures you can make an informed choice for your specific culinary or industrial needs.

Makmur Amanah Sejahtera provides high-quality palm products such as Palm Kernel Expeller, Palm Kernel Shell, Crude Palm Oil, Palm Kernel Oil, etc. Kindly contact us at WhatsApp +6282140002198 or email us at admin@makmuramanah.co.id.Looking for High-Quality Palm Products?