Table of Contents

- What is RBD Palm Olein? An Overview

- The Refining Process: What Does “RBD” Mean?

- Understanding Cloud Point: A Guide to CP6, CP8, and CP10

- The Top 5 Commercial Uses of RBD Palm Olein

- Nutritional Profile and Health Considerations

- Sustainability and Full Circle Production

- Where to Source High-Quality RBD Palm Olein?

- Conclusion

What is RBD Palm Olein? An Overview

If you’ve ever checked the ingredients on a package of instant noodles, a bag of chips, or a tub of margarine, you’ve likely encountered palm oil. More specifically, you have probably seen RBD Palm Olein, one of the most widely used and versatile edible oils in the world. It is the liquid fraction obtained from the fractionation of palm oil after a rigorous refining, bleaching, and deodorizing process. This makes it a stable, cost-effective choice for countless food manufacturers.

While RBD Palm Olein is derived from the palm fruit’s mesocarp (flesh), the fruit’s core also yields valuable products like Palm Kernel and Palm Kernel Oil. This guide will explore everything you need to know about RBD Palm Olein, breaking down what “RBD” means and the crucial differences between its grades like CP6, CP8, and CP10. Understanding RBD Palm Olein is key to understanding modern food production.

The Refining Process: What Does “RBD” Mean?

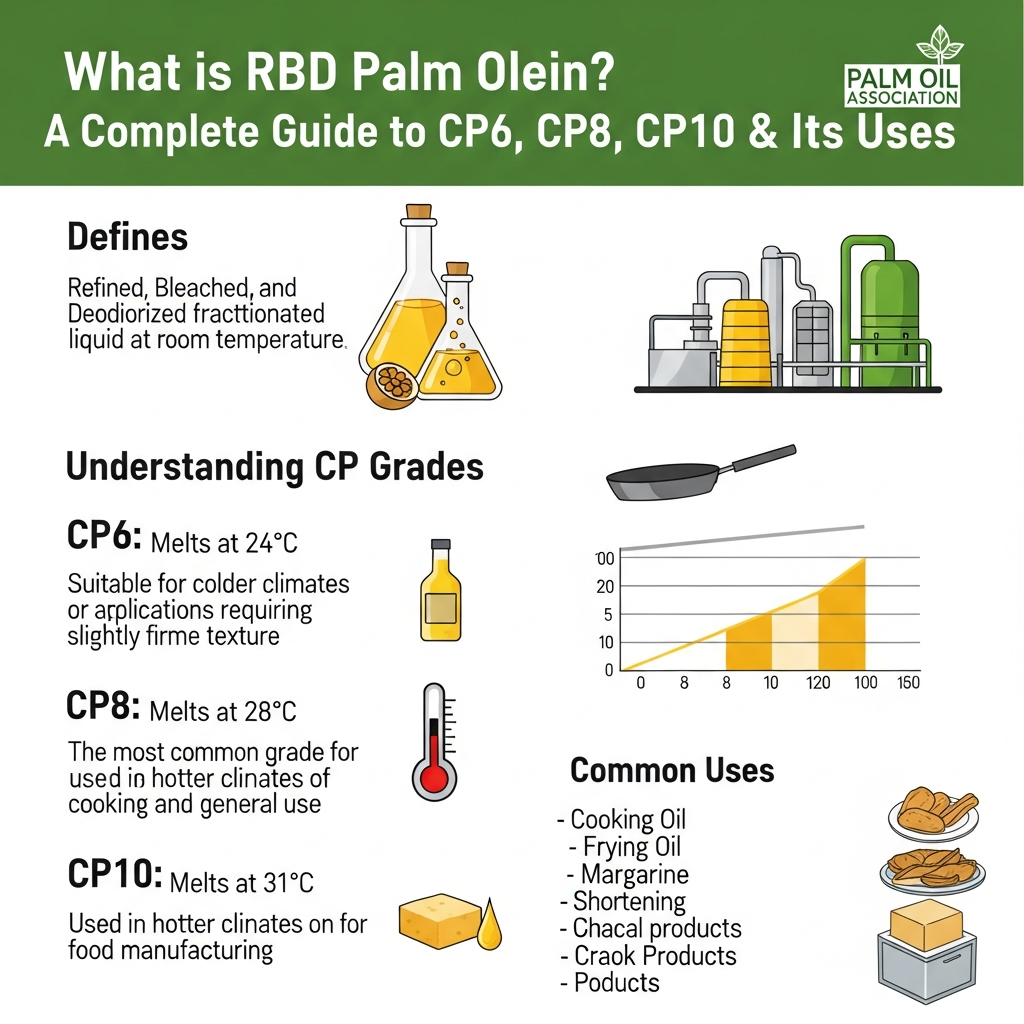

The “RBD” in RBD Palm Olein stands for “Refined, Bleached, and Deodorized.” This multi-stage process transforms Crude Palm Oil, which is naturally reddish and has a strong taste, into the neutral, stable, and light-yellow RBD Palm Olein used globally. Each step is critical to achieving the final product’s desired qualities.

- Refining: This initial stage removes free fatty acids (FFAs) and other impurities like gums. High FFA content can cause oil to smoke and spoil quickly, so this step is essential for creating a stable cooking oil.

- Bleaching: Next, the oil is treated with natural bleaching clays under a vacuum. This process strips away the carotenoids (which give crude palm oil its red color) and other unwanted pigments, resulting in a light, golden-yellow liquid.

- Deodorizing: In the final step, the oil is heated with steam under a high vacuum. This removes any residual odors and flavors, yielding a completely bland and neutral oil that won’t interfere with the taste of food products.

Understanding Cloud Point: A Guide to CP6, CP8, and CP10

After the RBD process, palm oil undergoes fractionation. This involves cooling the oil to crystallize the solid fat (stearin) and separating it from the liquid fat (olein). The resulting RBD Palm Olein is then graded based on its “Cloud Point” (CP), which is the temperature at which the oil begins to look cloudy or solidify. The lower the cloud point, the clearer the oil remains in cooler temperatures.

1. RBD Palm Olein CP10

RBD Palm Olein CP10 is the most common and widely produced grade. It has a maximum cloud point of 10° Celsius (50° F). While it performs exceptionally well for frying and general cooking in temperate and tropical climates, it may become cloudy and thick in colder regions.

2. RBD Palm Olein CP8 (Super Olein)

Often referred to as “Super Olein,” RBD Palm Olein CP8 has a maximum cloud point of 8° Celsius (46.4° F). This lower cloud point is achieved through a more intensive fractionation process. CP8 is preferred for applications like salad dressings and mayonnaise or for use in cooler climates where CP10 might solidify. Its ability to stay liquid at lower temperatures makes it a more versatile option.

3. RBD Palm Olein CP6 (Super Olein)

CP6 is an even higher grade of Super Olein with a maximum cloud point of just 6° Celsius (42.8° F). It is the most expensive of the three due to the double fractionation required. This premium RBD Palm Olein is used in specialized applications like infant formula, high-quality cooking oils, and pharmaceutical products where clarity and liquidity at low temperatures are paramount.

The Top 5 Commercial Uses of RBD Palm Olein

The stability, neutral flavor, and cost-effectiveness of RBD Palm Olein make it a preferred choice across numerous industries. Here are five of its most significant applications.

1. Industrial Frying

From potato chips to instant noodles and fast food, RBD Palm Olein is the gold standard for industrial frying. Its high smoke point (around 235°C or 455°F) and excellent resistance to oxidation mean it doesn’t break down easily, ensuring a longer fry-life and a crispy final product. For more on oil stability, you can review studies from the Journal of Food Science and Technology.

2. Margarine and Spreads

It provides the semi-solid consistency needed for margarines, shortenings, and other spreads without requiring hydrogenation. This makes it a valuable ingredient for producing trans-fat-free products, a significant benefit for health-conscious consumers.

3. Confectionery and Baked Goods

In baking, RBD Palm Olein contributes to the texture, mouthfeel, and shelf life of products like cookies, biscuits, and cakes. It’s also used in chocolate coatings and fillings to prevent melting at room temperature and provide a smooth finish.

4. Infant Formula

High-grade CP6 and CP8 palm olein is a key ingredient in many infant formulas. This is because its fatty acid profile, particularly its palmitic acid content, helps mimic the composition of human breast milk. The World Health Organization provides extensive guidelines on infant nutrition standards.

5. Non-Food Applications

Beyond the kitchen, derivatives of palm oil are essential in making soaps, detergents, cosmetics, and personal care products. It also serves as a feedstock for producing biodiesel, a renewable energy source.

Nutritional Profile and Health Considerations

RBD Palm Olein is composed of roughly 50% saturated fatty acids (primarily palmitic acid) and 50% unsaturated fatty acids (primarily oleic acid). It is also a rich natural source of Vitamin E, specifically tocotrienols, which are powerful antioxidants.

The health impacts of palm oil are often debated due to its high saturated fat content. However, many health authorities, such as the Harvard T.H. Chan School of Public Health, emphasize that the overall dietary pattern is more important than a single ingredient. When consumed in moderation as part of a balanced diet, it can be a stable, trans-fat-free cooking option.

Sustainability and Full Circle Production

The booming demand for palm oil has led to significant environmental concerns, including deforestation and loss of biodiversity. In response, the industry has pushed towards sustainable practices. When sourcing RBD Palm Olein, it is crucial to look for certifications like the Roundtable on Sustainable Palm Oil (RSPO), which sets strict environmental and social criteria.

A key part of sustainability is utilizing the entire harvest. Beyond the oil, the process yields other valuable resources. The leftover pulp from the kernel becomes Palm Kernel Expeller, a protein-rich animal feed. The hard Palm Kernel Shell is a clean, efficient biofuel. Even the Oil Palm Fruit Bunch is used as fertilizer or biomass energy, ensuring nothing goes to waste.

Where to Source High-Quality RBD Palm Olein?

Looking for High-Quality Palm Products?

Makmur Amanah Sejahtera provides high-quality palm products such as Palm Kernel Expeller, Palm Kernel Shell, Crude Palm Oil, Palm Kernel Oil, etc. Kindly contact us at WhatsApp +6282140002198 or email us at admin@makmuramanah.co.id.

Conclusion

From its complex production process to its varied grades, RBD Palm Olein is far more than just a simple cooking oil. It is a foundational ingredient in the global food supply chain, valued for its stability, versatility, and cost-effectiveness. By understanding the differences between CP6, CP8, and CP10, and by making conscious choices to support sustainable sourcing, consumers and manufacturers alike can continue to benefit from this remarkable commodity while protecting our planet.