Table of Contents

- What Exactly is RBD Palm Olein? Decoding the Name

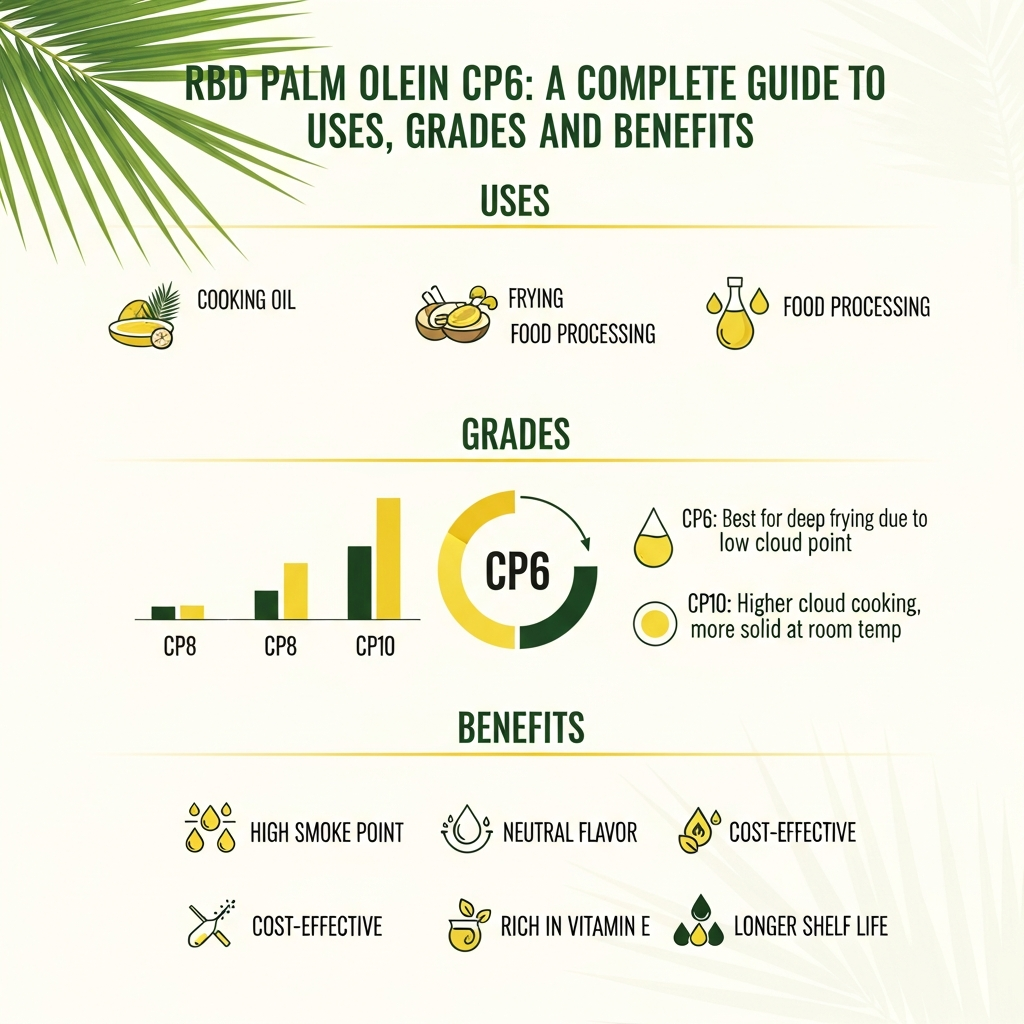

Understanding the “CP6” Grade in RBD Palm Olein CP6

How is RBD Palm Olein CP6 Made? A Step-by-Step Process

Key Benefits and Characteristics of RBD Palm Olein CP6

Common Uses of RBD Palm Olein CP6 in the Food Industry

RBD Palm Olein CP6 vs. Other Common Cooking Oils

Navigating Health and Sustainability Concerns

Your Trusted Supplier of Palm Products

Conclusion: Why RBD Palm Olein CP6 is a Global Staple

Have you ever wondered what makes your favorite fried snacks so consistently crispy and delicious? The secret often lies in the type of oil used, and one of the most prevalent yet misunderstood oils in the global food industry is RBD Palm Olein CP6. This premium cooking oil is a powerhouse of stability and versatility, essential for everything from instant noodles to industrial-scale frying.

This guide will demystify everything about RBD Palm Olein CP6, exploring its production process, unique characteristics, widespread uses, and how it compares to other oils on the market. Whether you’re a food industry professional or a curious consumer, you’ll gain a clear understanding of this vital culinary ingredient.

What Exactly is RBD Palm Olein? Decoding the Name

To truly understand RBD Palm Olein CP6, let’s break down its name. Each part of the name describes a specific step in its production or a key characteristic of the final product, which sets it apart from crude palm oil.

RBD: Refined, Bleached, and Deodorized

The “RBD” signifies a three-step purification process that transforms crude palm oil into a stable, neutral oil suitable for cooking. This process is standard for many vegetable oils.

- Refined: This initial step removes impurities and free fatty acids (FFAs) that can cause the oil to smoke and spoil quickly. Refining improves the oil’s quality and shelf life.

Bleached: The oil is filtered through natural clays to remove pigments, like the reddish-orange carotenoids found in crude palm oil. This results in a light, golden-yellow color.

Deodorized: Steam is used under a vacuum to remove any volatile compounds that create unwanted odors and flavors. This leaves the oil with a completely neutral taste, ensuring it doesn’t alter the flavor of the food.

Palm Olein: The Liquid Fraction

After the RBD process, palm oil undergoes a process called fractionation. The oil is cooled, which causes it to separate into a solid part (stearin) and a liquid part. The liquid portion is Palm Olein, which remains fluid at room temperature and is lower in saturated fat than whole palm oil. This liquid fraction is the primary component of bottled cooking oil.

Understanding the “CP6” Grade in RBD Palm Olein CP6

The “CP” stands for Cloud Point, which is the temperature at which the oil starts to become cloudy or solidify. The number indicates the maximum cloud point in degrees Celsius. Therefore, RBD Palm Olein CP6 has a maximum cloud point of 6°C.

This low cloud point is a sign of superior quality. It means the oil will remain clear and liquid even in cooler climates or during refrigerated transport, preventing crystallization. This stability makes CP6 a premium grade compared to CP8 or CP10, which cloud at higher temperatures (8°C and 10°C, respectively). For applications requiring consistent liquidity, RBD Palm Olein CP6 is the preferred choice.

How is RBD Palm Olein CP6 Made? A Step-by-Step Process

The creation of high-quality RBD Palm Olein CP6 is a meticulous process designed to ensure purity, stability, and performance. Here’s a simplified look at the journey from fruit to bottle.

- Harvesting & Sterilization: Fresh Oil Palm Fruit Bunch are harvested and quickly sterilized with steam to halt enzyme activity that would otherwise increase free fatty acids.

Threshing & Digestion: The fruit is separated from the bunches (threshing) and then heated and mashed (digestion) to break down the oil-bearing cells.

Pressing & Clarification: The digested fruit is pressed to extract the Crude Palm Oil (CPO) and separate the Palm Kernel. The CPO is then clarified to remove water and solid impurities.

RBD Process: The CPO undergoes the Refining, Bleaching, and Deodorizing process described earlier to purify it.

Fractionation: This is the critical final step. The RBD palm oil is carefully cooled under controlled conditions, allowing the higher-melting-point stearin to crystallize. These crystals are then filtered out, leaving behind the liquid olein. For RBD Palm Olein CP6, this process is optimized to achieve the low 6°C cloud point. For more detail on this, check out this overview of palm oil fractionation on ScienceDirect.

Beyond the oil, the palm fruit provides other valuable resources. The kernel is processed to produce Palm Kernel Oil, a different type of oil with unique properties. The leftover pulp, known as Palm Kernel Expeller, is a protein-rich ingredient used in animal feed. Even the hard Palm Kernel Shell is utilized as a clean, efficient biofuel.

Key Benefits and Characteristics of RBD Palm Olein CP6

The popularity of RBD Palm Olein CP6 stems from a unique combination of characteristics that make it ideal for a wide range of culinary applications.

- High Smoke Point: With a smoke point of around 235°C (455°F), it is exceptionally stable at high temperatures. This makes it perfect for deep frying, as it resists breaking down and producing harmful compounds. Learn more about the importance of smoke points from Serious Eats.

Excellent Oxidative Stability: The oil is naturally resistant to oxidation, which means it doesn’t go rancid easily. This translates to a longer shelf life for both the oil and the products made with it.

Neutral Flavor and Odor: Because it’s fully deodorized, RBD Palm Olein CP6 doesn’t impart any flavor to food, allowing the natural taste of the ingredients to shine through.

Rich in Vitamin E: Palm oil is a significant source of Vitamin E, particularly tocotrienols, which have powerful antioxidant properties. Studies published on sites like the National Center for Biotechnology Information (NCBI) have explored these benefits.

Cost-Effective and Efficient: Palm trees have a very high yield per hectare compared to other oilseed crops, making RBD Palm Olein CP6 an economically efficient and reliable option for the global food supply chain.

Common Uses of RBD Palm Olein CP6 in the Food Industry

Thanks to its beneficial properties, RBD Palm Olein CP6 is a cornerstone of the food manufacturing industry. You can find it in a vast array of products.

Industrial Frying

This is the primary application. The oil’s stability makes it the go-to choice for frying snacks like potato chips, instant noodles, donuts, and frozen french fries. It can be used for longer periods before needing replacement, offering significant cost savings for businesses.

Cooking and Baking

Sold as a general-purpose cooking oil, RBD Palm Olein CP6 is used in households and restaurants worldwide. It is also a key ingredient in the production of margarine, shortening, and various confectionery fats used in baking.

Blended Vegetable Oils

Its neutral profile and cost-effectiveness make it an excellent base for creating blended vegetable oils. It is often mixed with other oils like soybean or sunflower oil to create products with specific characteristics.

RBD Palm Olein CP6 vs. Other Common Cooking Oils

How does RBD Palm Olein CP6 stack up against other popular oils? Here’s a quick comparison:

| Feature | RBD Palm Olein CP6 | Soybean Oil | Sunflower Oil (High-Oleic) | Canola Oil |

|---|---|---|---|---|

| Smoke Point | ~235°C (455°F) | ~230°C (450°F) | ~232°C (450°F) | ~204°C (400°F) |

| Flavor | Neutral | Neutral | Neutral | Neutral |

| Primary Use | Deep Frying, Industrial | General Cooking, Margarine | Frying, Baking | General Cooking, Salad Dressing |

| Key Benefit | High Stability, Cost | Versatility | High Monounsaturated Fats | Low Saturated Fat |

Navigating Health and Sustainability Concerns

No discussion of palm oil is complete without addressing the health and environmental considerations. It’s crucial to look at the facts and understand the nuances.

Health Profile

RBD Palm Olein CP6 has a balanced fatty acid profile, with roughly equal parts saturated and unsaturated fats. It is naturally free of the harmful trans fats found in partially hydrogenated oils. Like all fats and oils, it should be consumed in moderation as part of a balanced diet. The World Health Organization (WHO) provides guidelines on dietary fat consumption for overall health.

Sustainability

The palm oil industry has faced significant criticism regarding deforestation and its impact on biodiversity. In response, a global movement towards sustainable production has gained momentum. Organizations like the Roundtable on Sustainable Palm Oil (RSPO) have established stringent criteria for certifying palm oil that is produced responsibly.

When sourcing RBD Palm Olein CP6, choosing suppliers committed to RSPO standards is crucial for supporting environmental protection, safeguarding wildlife habitats, and ensuring fair treatment for workers.

Your Trusted Supplier of Palm Products

Looking for High-Quality Palm Products?

Makmur Amanah Sejahtera provides high-quality palm products such as Palm Kernel Expeller, Palm Kernel Shell, Crude Palm Oil, Palm Kernel Oil, etc. Kindly contact us at WhatsApp +6282140002198 or email us at admin@makmuramanah.co.id.

Conclusion: Why RBD Palm Olein CP6 is a Global Staple

RBD Palm Olein CP6 is far more than just another cooking oil. It is a highly refined, premium-grade product engineered for performance, stability, and versatility. Its high smoke point, neutral flavor, and exceptional resistance to rancidity make it an indispensable ingredient for the global food industry, ensuring that products from snacks to baked goods are consistent and high-quality.

By understanding what the “RBD” and “CP6” designations mean, you can appreciate the quality control behind this oil. As consumers and industry professionals become more conscious of sustainability, opting for certified sources ensures that we can continue to benefit from this efficient and versatile oil while protecting our planet.