RBD Palm Olein CP8 vs CP10: The #1 Ultimate Guide for 2025

Table of Contents

- What Exactly is RBD Palm Olein?

- Understanding Cloud Point: The Core Difference in RBD Palm Olein CP8 vs CP10

- Technical Specifications Showdown: RBD Palm Olein CP8 vs CP10

- Common Applications and Uses of RBD Palm Olein CP8

- Common Applications and Uses of RBD Palm Olein CP10

- How to Choose: Key Factors in the RBD Palm Olein CP8 vs CP10 Decision

- The Broader Palm Oil Ecosystem

- Conclusion

When navigating the world of edible oils, particularly palm oil, the terminology can get confusing. If you’re in the food industry, you’ve likely encountered the terms CP8 and CP10. Understanding the critical debate of RBD Palm Olein CP8 vs CP10 is essential for choosing the right product for your application, climate, and budget. This guide breaks down everything you need to know.

What Exactly is RBD Palm Olein?

First, let’s decipher the name. “RBD” stands for Refined, Bleached, and Deodorized. This is a crucial purification process that Crude Palm Oil (CPO), extracted from the Oil Palm Fruit Bunch, undergoes to become a stable, odorless, and neutral-flavored cooking oil. This process removes impurities, free fatty acids (FFAs), and pigments.

It is important to distinguish RBD Palm Olein from oils derived from the fruit’s seed, or Palm Kernel. That seed is crushed to produce Palm Kernel Oil (PKO), which has a different fatty acid profile and applications.

The next step is fractionation, where the RBD palm oil is cooled to crystallize and separate its solid and liquid components. The solid fat is called Palm Stearin, while the liquid portion is RBD Palm Olein. This liquid fraction is the most widely used form of palm oil globally, prized for its versatility and stability. For more on this process, you can explore resources from the Malaysian Palm Oil Council (MPOC).

Understanding Cloud Point: The Core Difference in RBD Palm Olein CP8 vs CP10

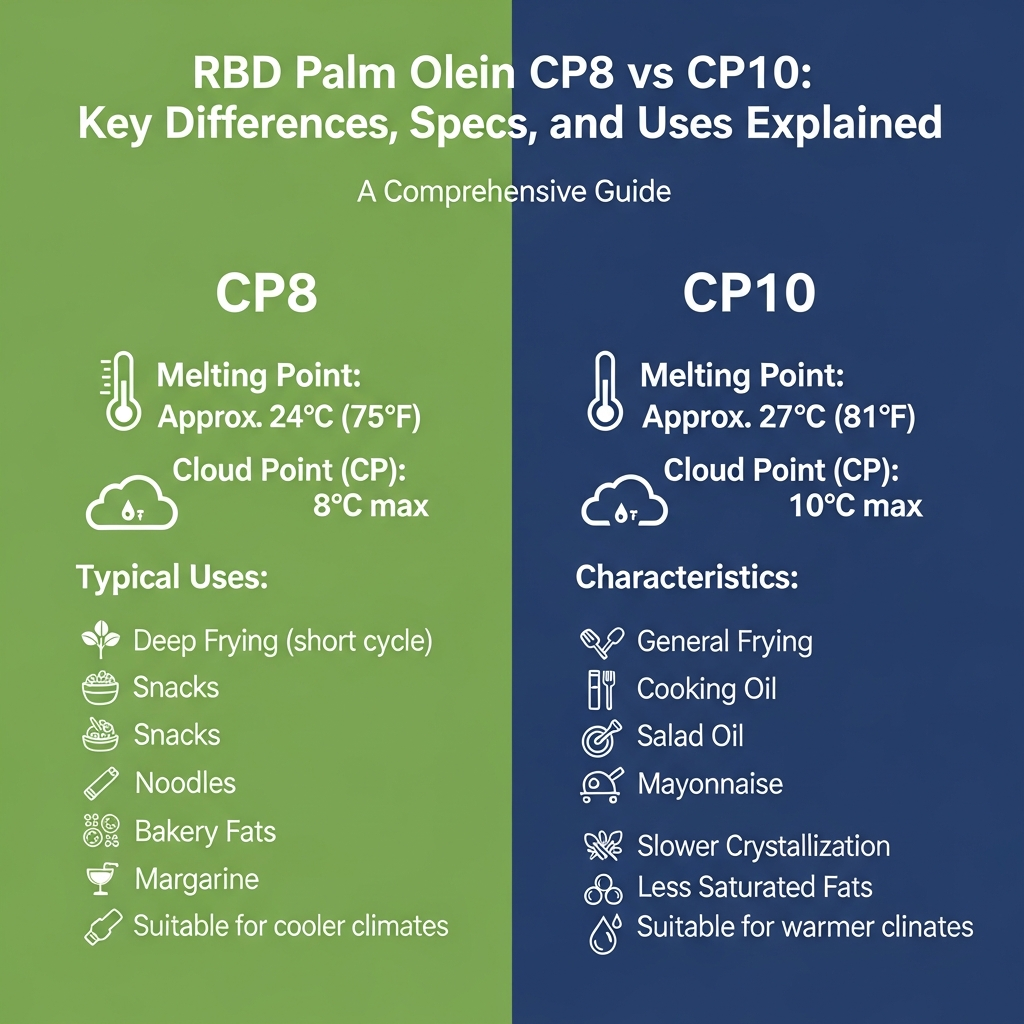

The number that follows “CP” is the most important factor in the RBD Palm Olein CP8 vs CP10 comparison. “CP” stands for Cloud Point.

Cloud Point is the temperature at which the oil starts to become cloudy or hazy as it cools due to the formation of wax crystals. This metric is a key indicator of an oil’s performance in cooler temperatures.

- RBD Palm Olein CP10 has a cloud point of 10° Celsius (50°F).

- RBD Palm Olein CP8 has a cloud point of 8° Celsius (46.4°F).

This two-degree difference is significant. CP8 is produced through a more intensive process, often called double fractionation, to remove more saturated fatty acids. This results in an oil that remains clear and liquid at lower temperatures, making it a “super olein.”

Technical Specifications Showdown: RBD Palm Olein CP8 vs CP10

Beyond the cloud point, there are other technical specifications where these two oils differ slightly. Understanding these specs provides a clearer picture when making a decision in the RBD Palm Olein CP8 vs CP10 debate.

| Specification | RBD Palm Olein CP10 | RBD Palm Olein CP8 |

|---|---|---|

| Cloud Point | Max 10°C | Max 8°C |

| Iodine Value (IV) | 56 min | 57.5 min |

| Free Fatty Acids (FFA) | Max 0.1% | Max 0.1% |

| Moisture & Impurities (M&I) | Max 0.1% | Max 0.1% |

| Color (5.25″ Lovibond) | 3 Red Max | 3 Red Max |

The most notable difference in this table, besides the Cloud Point, is the Iodine Value (IV). IV measures the degree of unsaturation in a fat. A higher IV, as seen in CP8, indicates a higher proportion of unsaturated fats, which contributes to its lower melting and cloud points. This concept is well-documented in food science journals like the Journal of Food Chemistry.

Common Applications and Uses of RBD Palm Olein CP8

Thanks to its lower cloud point and superior cold stability, CP8 is considered a premium product. It is the ideal choice for applications where clarity and liquidity at cooler ambient temperatures are essential.

- Bottling for Retail: It is perfect for bottled cooking oil sold in supermarkets, especially in countries with temperate or colder climates, as it is less likely to solidify on the shelf.

- Salad Dressings: Its ability to remain liquid when refrigerated makes it a suitable base for salad dressings and mayonnaise.

- Shallow Frying: While excellent for all types of frying, its higher cost often reserves it for premium cooking applications rather than industrial deep-frying.

Common Applications and Uses of RBD Palm Olein CP10

RBD Palm Olein CP10 is the most widely produced and consumed palm olein globally. Its balance of performance and cost-effectiveness makes it the workhorse of the food industry, particularly in tropical and warmer climates where clouding is not a concern.

- Industrial Deep-Frying: This is the number one use. Its high smoke point and oxidative stability make it perfect for frying instant noodles, potato chips, donuts, and fast food.

- General Cooking: It serves as a standard cooking oil in millions of households and restaurants worldwide.

- Manufacturing: It’s a key ingredient in the production of margarine, shortening, and confectionery fats.

How to Choose: Key Factors in the RBD Palm Olein CP8 vs CP10 Decision

Choosing between CP8 and CP10 comes down to three primary factors in the RBD Palm Olein CP8 vs CP10 decision:

- Climate and Application: If your product will be sold or used in a colder region, or if it needs to remain liquid under refrigeration (like salad dressing), CP8 is the clear winner. For high-heat industrial frying in warmer regions, CP10 is more than sufficient.

- Cost: Due to the extra fractionation step, CP8 is consistently more expensive than CP10. For large-scale operations where cost is a major driver, CP10 is the more economical choice.

- Quality Perception: For a retail product marketed as “premium,” the superior cold stability and clarity of CP8 can be a significant selling point.

When sourcing, it’s also important to consider sustainability. Look for suppliers certified by the Roundtable on Sustainable Palm Oil (RSPO) to ensure responsible production practices. For further guidance on edible oil sourcing, you can check out our comprehensive Buyer’s Guide to Vegetable Oils.

The Broader Palm Oil Ecosystem

Understanding the RBD Palm Olein CP8 vs CP10 choice is key for edible oil buyers, but it’s just one part of a larger ecosystem. The same palm fruit processing yields other valuable resources. After the oil is extracted, the leftover fibrous cake becomes Palm Kernel Expeller (PKE), a protein-rich component for animal feed. The hard pits, known as Palm Kernel Shell (PKS), are converted into a high-grade, low-carbon biofuel. This demonstrates the incredible efficiency and sustainability of the palm oil supply chain.

Conclusion: The Final Word on RBD Palm Olein CP8 vs CP10

The RBD Palm Olein CP8 vs CP10 debate doesn’t have a single winner; it has the right choice for a specific need. CP10 is the cost-effective, versatile industry standard perfect for frying and manufacturing in most parts of the world. CP8 is the premium “super olein,” offering enhanced cold stability at a higher price point, making it ideal for bottling and specialized applications in cooler climates.

By understanding the fundamental difference in their cloud points and aligning that with your application, climate, and budget, you can make an informed decision that optimizes both product quality and cost-efficiency. This knowledge is key to leveraging these widely used edible oils effectively. As per standards laid out by global bodies like the FAO Codex Alimentarius, both are high-quality oils when sourced correctly.

Makmur Amanah Sejahtera provides high-quality palm products such as Palm Kernel Expeller, Palm Kernel Shell, Crude Palm Oil, Palm Kernel Oil, etc. Kindly contact us at WhatsApp +6282140002198 or email us at admin@makmuramanah.co.id.