RBD Palm Olein CP8 vs CP10: Your #1 Ultimate Guide for 2025

Table of Contents

- What is RBD Palm Olein?

- Understanding “CP”: Why the Cloud Point Matters

- A Deep Dive into RBD Palm Olein CP10

- A Closer Look at RBD Palm Olein CP8

- The Ultimate Showdown: CP8 vs. CP10 Palm Olein

- Which One is Right for You? A 2025 Practical Guide

- Frequently Asked Questions (FAQ)

- Conclusion: Making the Right Choice

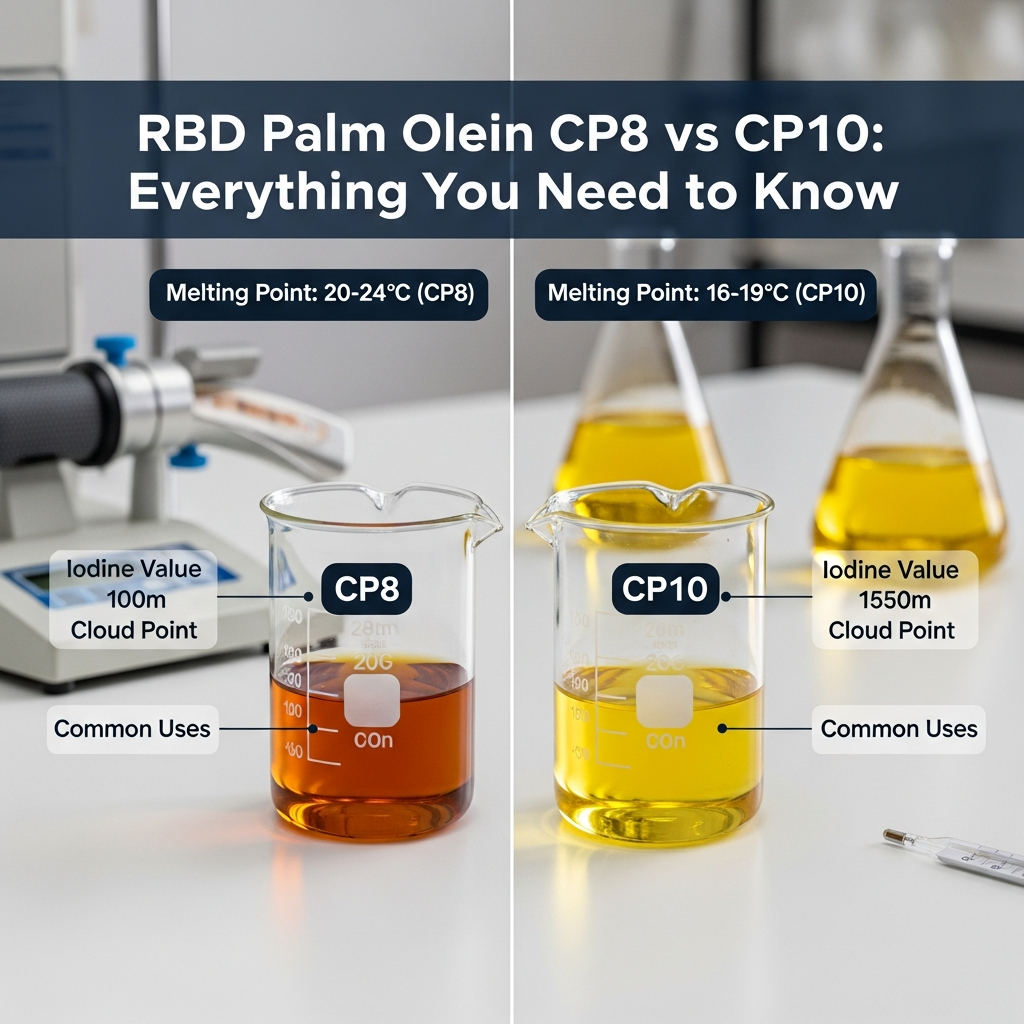

When navigating the world of edible oils, the specifications can be confusing. For those in the food industry, choosing the right cooking oil is a critical decision that impacts product quality, stability, and cost. This is especially true when considering the RBD Palm Olein CP8 vs CP10 debate. While they may sound similar, their key differences can significantly affect your final product. This guide will break down everything you need to know to make an informed choice.

What is RBD Palm Olein?

Before comparing CP8 and CP10, let’s define the terms. RBD Palm Olein is a popular cooking oil derived from Crude Palm Oil. This oil is extracted from the flesh of the Oil Palm Fruit Bunch, while the seed provides other valuable products like Palm Kernel and its derivative, Palm Kernel Oil. The “RBD” in Palm Olein stands for Refined, Bleached, and Deodorized—a standard process that removes impurities, pigments, and odors. This results in a stable, bland-flavored, and light-colored oil.

Olein is the liquid fraction obtained from palm oil after a process called fractionation. This makes it ideal for high-temperature cooking and frying. The key difference between various grades of palm olein lies in their Cloud Point (CP).

Understanding “CP”: Why the Cloud Point Matters

The “CP” in CP8 and CP10 refers to the Cloud Point. This is the temperature at which the oil begins to become cloudy or hazy as wax crystals start to form. A lower cloud point indicates that the oil will remain liquid and clear at lower temperatures.

This is a crucial factor for product appearance and stability, especially in temperate or colder climates. An oil with a high cloud point might solidify or look unappealing on a supermarket shelf during winter, which can deter customers. As defined by food science resources like ScienceDirect, the cloud point is a key indicator of an oil’s performance in cooler conditions.

A Deep Dive into RBD Palm Olein CP10

RBD Palm Olein CP10 is the most common and widely used grade of palm olein globally. It has a maximum cloud point of 10° Celsius (50° F). This means it will start to become cloudy if the temperature drops to 10°C.

Because it is less processed than its CP8 counterpart, CP10 is generally more affordable and readily available. Its balance of stability, performance, and cost makes it the go-to choice for general frying, industrial food production, and cooking in warmer climates where ambient temperatures stay well above its cloud point. The vast majority of instant noodles, snacks, and fried foods utilize CP10.

A Closer Look at RBD Palm Olein CP8

RBD Palm Olein CP8, sometimes referred to as “Super Olein,” is a more premium grade. It undergoes further fractionation to lower its cloud point to a maximum of 8° Celsius (46.4° F). This extra processing step removes more of the saturated fatty acids that tend to solidify at cooler temperatures.

This lower cloud point makes CP8 a better choice for applications where clarity at lower temperatures is essential. It’s often used for bottled cooking oil sold in temperate regions, as a salad oil, and in the production of specialty fats and shortenings. The choice between CP8 and CP10 often comes down to this single factor of cold stability.

The Ultimate Showdown: CP8 vs. CP10 Palm Olein

Let’s put these two oils head-to-head to clearly understand their differences. While the cloud point is the main distinction, it leads to other variations in performance and application.

1. Cloud Point and Cold Stability

As established, this is the primary difference. CP10 solidifies at 10°C, while CP8 remains liquid down to 8°C. This 2-degree difference is significant for liquid oil products that might be stored in unheated warehouses or transported during colder months. For a consumer product, a cloudy oil can be mistaken for a spoiled one, making CP8 the safer choice for presentation.

2. Applications and Performance

The choice between these two oils often depends entirely on the end-use. CP10 is the workhorse of the food industry—perfect for deep-frying chips, doughnuts, and other snacks. CP8 is preferred for salad dressings, mayonnaise, and premium liquid frying oils where clarity is paramount.

3. Processing and Purity

To achieve the lower cloud point, CP8 undergoes an additional step of fractionation. This makes it a more refined product. This extra step can also result in a slightly lower content of Free Fatty Acids (FFA) and a different Iodine Value (IV), a measure of the oil’s unsaturation. According to journals on lipid technology, lower FFA contributes to a higher smoke point and longer shelf life.

4. Price and Availability

The additional processing required to produce CP8 makes it more expensive than CP10. The yield of CP8 from crude palm oil is also lower, contributing to its premium price. Consequently, CP10 is more widely available and is traded in much larger volumes on the global commodity markets, as tracked by sources like Reuters.

Which One is Right for You? A 2025 Practical Guide

Choosing between RBD Palm Olein CP8 vs CP10 is a strategic decision. Here’s a simple breakdown to help you decide:

- Choose CP10 if: You are a high-volume food manufacturer (e.g., snacks, noodles), your primary need is deep-frying, cost is a major factor, and your products are mainly sold and stored in warmer climates.

- Choose CP8 if: Your product is a liquid oil sold in retail bottles, you operate in a temperate or cold climate, product clarity on the shelf is a top priority, or you are producing salad dressings or mayonnaise.

A Note on Sustainability: Regardless of your choice, it’s crucial to source from suppliers committed to sustainable practices. Look for certifications from organizations like the Roundtable on Sustainable Palm Oil (RSPO) to ensure your supply chain is environmentally and ethically sound.

Frequently Asked Questions (FAQ)

What does RBD stand for again?

RBD stands for Refined, Bleached, and Deodorized. It’s a purification process used for many vegetable oils to make them suitable for cooking.

Is CP8 healthier than CP10?

There is no significant nutritional difference between CP8 and CP10. The primary difference is the cloud point, not the core nutritional profile. Both are stable frying oils.

Can I substitute CP10 for CP8 in a recipe?

For most hot applications like frying, yes. You can easily substitute CP10 for CP8. However, if you are making a product like a salad dressing that needs to stay liquid when refrigerated, you cannot substitute CP10 for CP8 without affecting the product’s quality and appearance.

Conclusion: Making the Right Choice

The comparison between CP8 and CP10 palm olein is not about which oil is “better,” but which is “right” for a specific application. CP10 is the cost-effective, versatile standard for general cooking and frying, especially in warm climates. CP8 is the premium choice, offering superior cold stability and clarity, making it ideal for bottled oils and applications in cooler regions.

By understanding these crucial differences, you can confidently select the right oil for your business needs. For a complete portfolio of high-quality palm products, from cooking oils to biomass solutions like Palm Kernel Shell and animal feed ingredients such as Palm Kernel Expeller, partnering with a trusted supplier is paramount.

Makmur Amanah Sejahtera provides high-quality palm products such as Palm Kernel Expeller, Palm Kernel Shell, Crude Palm Oil, Palm Kernel Oil, etc. Kindly contact us at WhatsApp +6282140002198 or email us at admin@makmuramanah.co.id.