Difference Between Palm Kernel Cake and Palm Kernel Expeller: Ultimate Guide (2025)

สารบัญ

- 1. Introduction: Clearing Up the Confusion2. Understanding the Source: The Humble Palm Kernel3. What is Palm Kernel Expeller (PKE)? The Mechanical Pressing Method4. What is Palm Kernel Cake (PKC)? The Solvent Extraction Method5. Key Differences: Palm Kernel Cake vs. Palm Kernel Expeller6. How Extraction Method Impacts Nutritional Value7. Are The Terms Used Interchangeably in the Industry?8. Core Applications in the Global Feed Industry9. Frequently Asked Questions (FAQ)10. Your Trusted Source for Palm Products11. Conclusion: Why the Difference Matters

1. Introduction: Clearing Up the Confusion

In the world of agricultural commodities and animal feed, terminology can be confusing. Two terms frequently used interchangeably, yet technically distinct, are palm kernel cake and palm kernel expeller. While they originate from the same source, the critical ความแตกต่างระหว่างเค้กเมล็ดปาล์มและเครื่องบีบเมล็ดปาล์ม lies in the oil extraction process, which significantly alters their nutritional profile and value. This 2025 guide provides the ultimate breakdown of this distinction.

Understanding this difference is not just an academic exercise. For livestock nutritionists, feed manufacturers, and farmers, choosing the right ingredient is crucial for optimizing animal health and productivity. This article will delve deep into the production methods, nutritional compositions, and applications of both products, giving you a clear understanding of their unique characteristics.

2. Understanding the Source: The Humble Palm Kernel

Before we differentiate the byproducts, let’s look at the source. It all begins with the ช่อผลปาล์มน้ำมัน. After the fleshy mesocarp of the oil palm fruit is processed to produce น้ำมันปาล์มดิบ, the hard nut remains. This nut is protected by a fibrous layer known as the ปาล์มเชลล์เคอร์เนล, a valuable biofuel. Inside this shell is the oil-rich เมล็ดในปาล์ม, the starting point for our two products.

This kernel is processed to extract ปาล์มของเคอร์เนลน้ำมัน, a valuable vegetable oil used in everything from cooking to cosmetics. The solid residue left behind after this extraction is what we know as either palm kernel expeller or cake. The method used to get the oil out is the deciding factor.

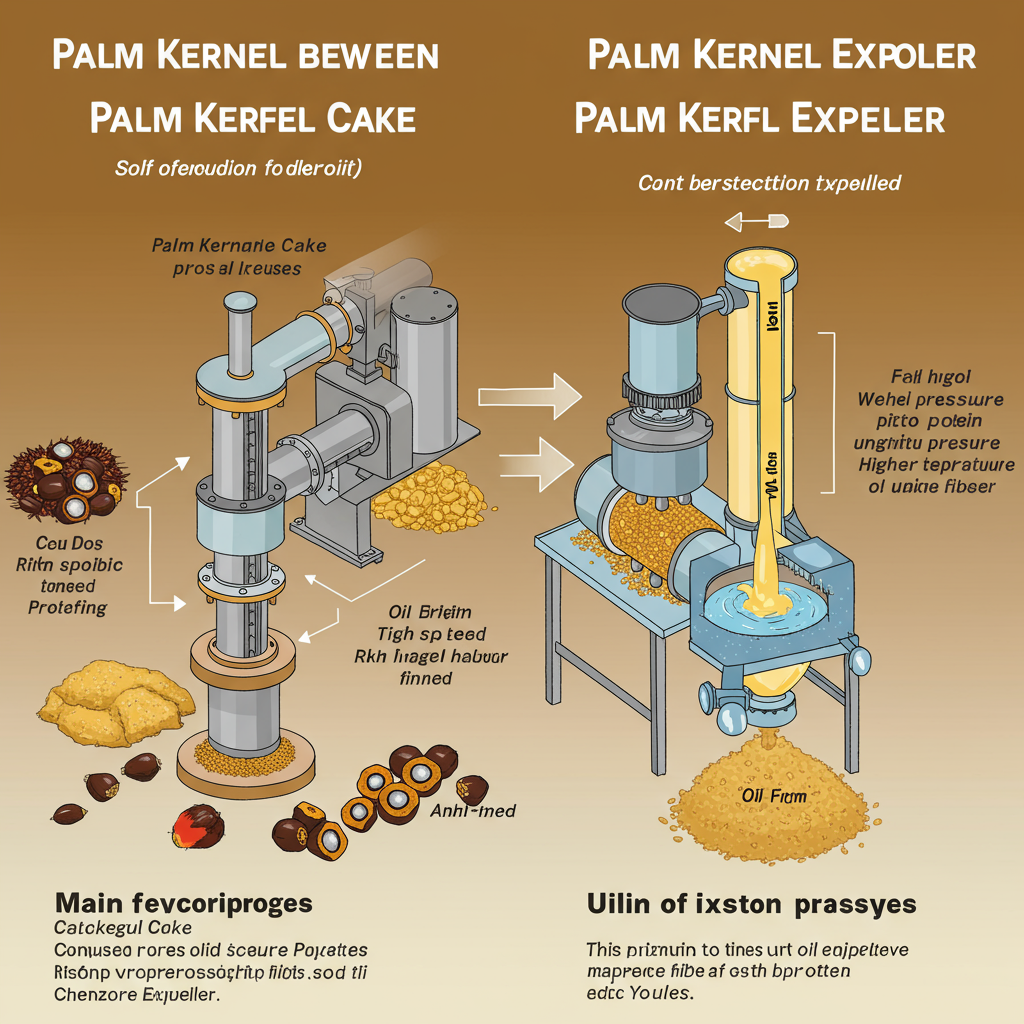

3. What is Palm Kernel Expeller (PKE)? The Mechanical Pressing Method

เครื่องบีบเมล็ดในปาล์ม (PKE) is the byproduct created through a mechanical extraction process. This method, often called screw pressing or expeller pressing, involves physically crushing the palm kernels under immense pressure to squeeze the oil out.

Because this process relies on mechanical force rather than chemical solvents, it is less efficient at removing all the oil. Consequently, PKE typically has a higher residual oil (fat) content, usually ranging from 8% to 12%. This higher fat content makes it more energy-dense, a desirable trait for certain types of animal feed, particularly for ruminants like cattle.

4. What is Palm Kernel Cake (PKC)? The Solvent Extraction Method

Palm Kernel Cake (PKC), in its strictest technical definition, refers to the residue left after a solvent extraction process. In this method, the palm kernels are first flaked and then washed with a solvent, typically hexane, which dissolves the oil.

The oil-solvent mixture is then separated, and the solvent is evaporated and recovered for reuse, leaving behind pure palm kernel oil. This chemical process is far more efficient, removing nearly all the oil from the kernel. As a result, true Palm Kernel Cake has a very low residual oil content, often between 1% and 3%. This lower fat content results in a product with a higher percentage of crude protein and fiber compared to PKE.

5. Key Differences: Palm Kernel Cake vs. Palm Kernel Expeller

To make the comparison clear, let’s break down the primary ความแตกต่างระหว่างเค้กเมล็ดปาล์มและเครื่องบีบเมล็ดปาล์ม in a simple table. This side-by-side view highlights the crucial distinctions that arise from their production methods.

| คุณสมบัติ | เครื่องบีบเมล็ดในปาล์ม (PKE) | เค้กเมล็ดปาล์ม (พีเคซี) |

|---|---|---|

| วิธีการสกัด | Mechanical (Screw Pressing) | Solvent Extraction (e.g., Hexane) |

| ปริมาณน้ำมันตกค้าง | Higher (8-12%) | Lower (1-3%) |

| Energy Value | Higher due to more fat | Lower due to less fat |

| Crude Protein % | Slightly lower | Slightly higher (concentrated due to oil removal) |

| Efficiency | Less efficient oil extraction | Highly efficient oil extraction |

| Common Use Case | Energy source for ruminant feed | Protein source where lower fat is desired |

6. How Extraction Method Impacts Nutritional Value

The variance in residual oil is the most significant nutritional factor. The 8-12% fat content in Palm Kernel Expeller provides a higher level of metabolizable energy, which is essential for energy-intensive activities like milk production in dairy cows or weight gain in beef cattle. For a deep dive into feedstuff composition, resources from institutions like Purdue University Extension เสนอข้อมูลอันมีค่า

Conversely, the lower fat Palm Kernel Cake has a higher concentration of protein and fiber. This makes it a valuable source of protein, although its high fiber content can limit its use in monogastric animals like poultry and swine, which cannot digest fiber as effectively as ruminants. The องค์การอาหารและเกษตรแห่งสหประชาชาติ (FAO) provides detailed profiles on the use of palm kernel products in animal diets.

7. Are The Terms Used Interchangeably in the Industry?

Despite the clear technical distinction, in commercial trade and everyday conversation, the term “Palm Kernel Cake” (PKC) is often used as a blanket term to describe the residue regardless of the extraction method. This is because mechanical pressing is the more common method used globally, so most of the “PKC” on the market is technically “PKE.”

However, for buyers and nutritionists creating precise feed formulations, it’s vital to specify the required residual oil content. Requesting a “Certificate of Analysis” is standard practice to confirm the nutritional specifications and understand the true difference between the palm kernel cake and palm kernel expeller being purchased. For more information on this topic, scientific journals like วิทยาศาสตร์โดยตรง often publish research on the variability of feed ingredients.

8. Core Applications in the Global Feed Industry

Both PKE and PKC are valued as a cost-effective ingredient in animal feed. Their primary application is for ruminant livestock (cattle, sheep, goats) due to their high fiber and moderate protein content. Ruminants’ unique digestive systems can efficiently break down the fibrous material to extract energy.

It is less common in pig and poultry diets because its high fiber content can hinder digestibility. Furthermore, the gritty texture of PKE can sometimes lead to lower palatability for these animals. As the industry moves towards more sustainable practices, byproducts like palm kernel meal play an important role, a value championed by organizations like the โต๊ะกลมเรื่องน้ำมันปาล์มที่ยั่งยืน (RSPO).

9. Frequently Asked Questions (FAQ)

What is the number one difference between palm kernel cake and palm kernel expeller?The main difference is the oil extraction method. Expeller (PKE) uses mechanical pressing, resulting in 8-12% residual oil. Cake (PKC) technically uses solvent extraction, leaving only 1-3% oil.เนื้อเค้กเมล็ดปาล์มดีต่อวัวนมหรือไม่?

Yes, it is an excellent and affordable source of protein, fiber, and energy for dairy cows and other ruminants. Its balanced nutritional profile supports milk production and general health.Why is residual oil content so important?

The residual oil content directly determines the energy value of the feed ingredient. High-energy feeds are crucial for animals with high metabolic demands, such as lactating cows or fattening livestock.

10. Your Trusted Source for Palm Products

Makmur Amanah Sejahtera จำหน่ายผลิตภัณฑ์ปาล์มคุณภาพสูง เช่น เครื่องบีบเมล็ดในปาล์ม เปลือกเมล็ดในปาล์ม น้ำมันปาล์มดิบ น้ำมันเมล็ดในปาล์ม ฯลฯ กรุณาติดต่อเราได้ที่ WhatsApp +6282140002198 หรือส่งอีเมลถึงเราที่ admin@makmuramanah.co.id

11. Conclusion: Why the Difference Matters

สรุปแล้วสิ่งสำคัญ ความแตกต่างระหว่างเค้กเมล็ดปาล์มและเครื่องบีบเมล็ดปาล์ม is not just a technicality; it’s a fundamental distinction that impacts nutritional value and application. Palm Kernel Expeller, from mechanical pressing, is an energy-rich feed due to its higher fat content. Palm Kernel Cake, from solvent extraction, is a protein-dense alternative with much lower fat.

While the industry often uses the names synonymously, professionals in the feed formulation sector must pay close attention to the specifications. By understanding the source, the process, and the resulting product, you can make more informed and effective decisions for your animal nutrition programs in 2025 and beyond.