RBD Palm Olein CP8: The Ultimate 2025 Guide to Specs & Uses

目录

In the vast world of edible oils, few are as versatile and globally significant as palm oil and its fractions. One of the most prominent liquid fractions is RBD Palm Olein CP8, a staple in kitchens and food manufacturing facilities worldwide. This comprehensive guide dives deep into what makes this oil unique, from its journey from the plantation to its final technical specifications and uses.

What Exactly Is RBD Palm Olein CP8?

Let’s break down the name. “RBD” stands for Refined, Bleached, and Deodorized. This describes the essential purification process the oil undergoes to become a premium cooking oil. The process removes impurities, neutralizes free fatty acids, lightens the color, and removes odors, resulting in a bland, stable, and high-quality product.

The “Olein” part signifies that it is the liquid fraction obtained from palm oil after a crystallization process called fractionation. The final part, “CP8,” refers to its Cloud Point of 8° Celsius (Max). This means the oil remains clear and liquid at temperatures above 8°C, only starting to become cloudy and solidify below this point. This characteristic is crucial for its performance in various climates and applications.

The Journey from Plantation to Product

The story of palm olein begins at the plantation with the harvesting of the 油棕果串. The fresh fruitlets are then pressed to extract the initial oil. This raw product, known as 毛棕榈油 (CPO), is the starting point for all refined palm products.

During the milling process, the valuable 棕榈仁 is also separated. This kernel is later crushed to produce another distinct product, 棕榈油, which has different properties and uses, particularly in the confectionery and oleochemical industries. The CPO then proceeds to the refinery for the RBD process and fractionation to create the final olein.

Key Specifications of RBD Palm Olein CP8

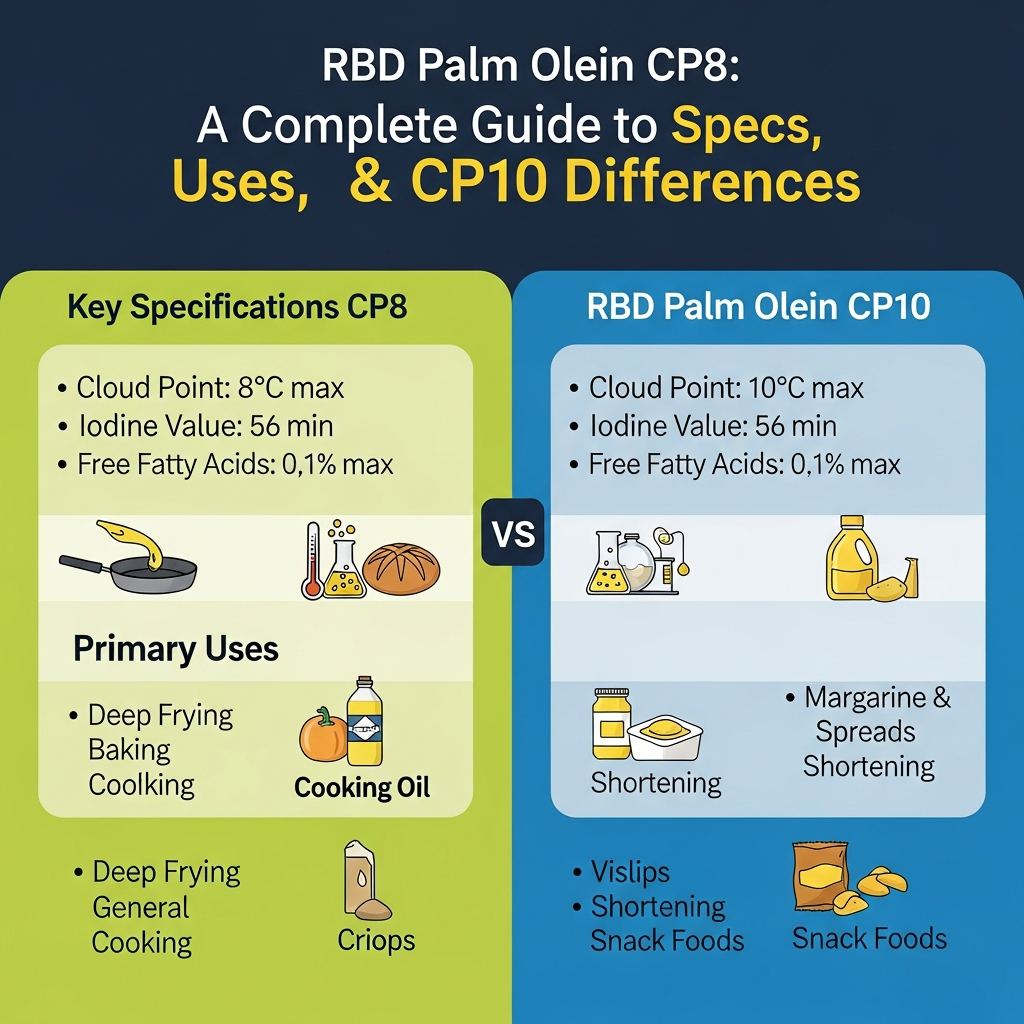

To truly understand RBD Palm Olein CP8, we need to look at its technical data sheet. These specifications determine its quality, stability, and suitability for different applications, adhering to strict international standards.

- Free Fatty Acids (FFA) (as % palmitic): Typically 0.1% max. Low FFA indicates high-quality refining and ensures a longer shelf life and higher smoke point.

- Moisture & Impurities (M&I): Usually 0.1% max. This measures water and non-oil materials, which should be minimal to prevent spoilage.

- Iodine Value (IV) (Wijs): 56 min. The iodine value indicates the degree of unsaturation. A higher IV is typical for liquid oils. For more on this, the ScienceDirect journal offers in-depth explanations.

- Cloud Point (CP): 8°C max. This is the defining feature of CP8, making it suitable for temperate and cooler regions.

- Color (5.25″ Lovibond cell): 3 Red max. This value ensures the oil is a light, appealing yellow.

常见用途和应用

The excellent stability and neutral flavor profile of this refined olein make it a preferred choice for a wide range of uses:

1. Deep Frying

This is where palm olein truly shines. Its high smoke point (around 235°C or 455°F) and resistance to oxidation make it ideal for industrial deep-frying of products like instant noodles, snacks, and french fries. It delivers a crisp texture without breaking down quickly, offering great value for food manufacturers.

2. General Cooking and Stir-Frying

In households across the globe, it is a popular all-purpose cooking oil. Its neutral taste doesn’t interfere with the natural flavors of ingredients, making it perfect for everyday culinary needs.

3. Manufacturing Margarine and Shortening

While it is a liquid oil, it can be blended with other fats and hydrogenated to produce margarines, spreads, and shortenings for the baking industry, contributing to the desired texture and mouthfeel.

CP8 vs. CP10 Palm Olein: What’s the Real Difference?

One of the most common questions concerns the difference between RBD Palm Olein CP8 and its counterpart, CP10. The distinction is simple yet significant, boiling down entirely to the Cloud Point.

- CP8 Palm Olein: Cloud Point of 8°C (Max).

- CP10 Palm Olein: Cloud Point of 10°C (Max).

This 2-degree difference means that CP8 olein remains liquid at a slightly lower temperature than CP10. This makes CP8 a better option for industries and consumers in temperate climates where ambient temperatures might cause CP10 to cloud or solidify. The choice is often based on geography, climate, and supply chain needs. For further reading, organizations like the 马来西亚棕榈油理事会 provide extensive resources on palm oil fractions.

Health and Sustainability Considerations

Nutritionally, palm olein is rich in Vitamin E and is free of trans fats. Like all oils, it should be consumed in moderation as part of a balanced diet, a fact supported by global health bodies like the 世界卫生组织(WHO).

The environmental impact of palm oil cultivation is a critical global conversation. To combat issues like deforestation, consumers should seek products from certified sustainable plantations. A holistic approach to sustainability also involves utilizing every part of the palm fruit. Byproducts like 棕榈壳 are used as a clean biofuel, while 棕榈核榨油机 becomes a valuable ingredient in animal feed. This “zero-waste” philosophy is central to modern, responsible production.

您值得信赖的棕榈产品供应商

Makmur Amanah Sejahtera 提供高品质的棕榈产品,如棕榈仁压榨机、棕榈仁壳、棕榈原油、棕榈仁油等。请通过 WhatsApp +6282140002198 与我们联系,或发送电子邮件至 admin@makmuramanah.co.id。

结论

综上所述, RBD Palm Olein CP8 is a highly functional, stable, and versatile edible oil that plays a crucial role in the global food supply. Its specific cloud point, excellent frying performance, and neutral profile make it an indispensable ingredient. By understanding its specifications and applications, and by choosing sustainably sourced options, users can leverage its benefits responsibly.